Spectroscopy

The following categories are available in Supercritical products:

1. Core Separations, USA

1. Core Separations, USA

Waters Corporations

Supercritical Fluid Chromatography System

Model: Acquity UPC² System

Ultra Performance Convergence Chromatography – Technology That breaks through chiral & achiral technologies.

*The ease of reversed phase meets the power of normal phase: With the ACQUITY UPC2 System, the orthogonal capability of normal-phase LC has been elevated to a mainstream technique: Convergence Chromatography.

* The chromatographic principles and selectivity of normal-phase LC

* The ease-of-use and method development simplicity of reversed-phase LC

* The use of gradients across the widest polarity range

* Chiral and achiral separations in one system, with unequaled speed and confidence

* Bringing ease-of-use to normal-phase LC

* The world's first convergence chromatography system

* Unparalleled resolving power and selectivity

* Retention mechanisms and orthogonality to RPLC

Enquiry Now

Model: Prep SFC 150 Mgm System

A greener approach to high throughput purification

Designed for high throughput, semi-prep to preparative scale purifications, the Prep SFC 150 Mgm™ System is made for repeat injection (bulk purification) of Chiral and Achiral compounds.

* The SFC 150 Mgm system has a maximum flow rate, CO2and co-solvent combined, up to 150mL/minute allowing use of 19mm and 30mm columns. It also has capacity for 6 fraction collection positions (2 Liter each).

* Controlled by the Waters Chromscope 2.0 SFC software running under Windows 10the user can take advantage of a new intuitive graphical interface. The Prep SFC 150 Mgm System operates at flow rates higher than traditional HPLC systems without significant increases in back pressure, allowing for high-speed SFC purification and improved resolution of compounds, leading to higher purity isolations.

* SFC systems utilize liquid Carbon Dioxide (CO2) as its main mobile phase in combination with one or more organic solvents resulting in faster equilibration, lower pressure drops across the column, solvent reduction and lower cost per sample. The process is reproducible and applicable to a wide range of compounds relevant in the Pharmaceutical, Life Sciences, Chemical Materials and Food & Environmental markets.

Enquiry Now

Model: Prep 350 SFC System

Waters' suite of bulk-scale supercritical fluid chromatography (SFC) purification systems offers the optimal system for the amount of sample you need to purify. These systems easily allow you to purify a large amount of one sample. When faster and more cost-effective means sustainable business operations, SFC is the purification technique that makes the difference.

Preparative-scale SFC 350 systems are automated systems that features co-solvent gradient, high pressure separators for quantitative recovery of purified products, such as enantiomers, complex synthetic chemicals and natural products. They are designed for chiral and achiral separations.

Features

* High pressure CO2 pump

* High pressure co-solvent pump

* Injection module

* UV-Vis detector

* Fraction collection module

* Automated Back Pressure Regulator (ABPR)

* ChromScope software

Enquiry Now

High Performance Liquid Chromatography System:

Model: Breeze QS HPLC

The Breeze QS HPLC System delivers routine analyses and robust performance day after day, providing the confidence you need to get the job done. Used in laboratories worldwide, chromatographers know that they’ll get reliable data in an easy-to-use platform.

With a choice of multiple components to build your own liquid chromatography system, and software that allows you to simplify the complete management of your chromatographic data, the Breeze QS HPLC System delivers world-class performance – affordably.

Features

* Reliable, Precise Results. Simple HPLC at its Best.

* HPLC made easy

* Flexible configurations to suit your needs

* Minimal training, less downtime, and more savings to the bottom line

* Quick and easy view of quantitative results

* Flexible reporting capabilities

Enquiry Now

Model: Alliance HPLC

Defined by dependability - today, and in the future:

* Time-tested, flexible, and reliable workhorse for your HPLC separations

* Integrated solvent and sample management with consistent system-to-system performance and high reproducibility

* A history of continued system improvements ensures the hightest in HPLC performance

* Simplify your daily LC system start-up with advanced software functionality

* Excellence through the years

* Performance that exceeds your method requirements

* Advancements in LC chemistry and mass detection

Features and Benefits:

- Quaternary solvent blendingsupports isocratic and gradient applications with 11 unique gradient profile curves. Blend up to 4 solvents in any proportion with Auto-Blend Technology. Compatible with a wide range of solvent types to support reversed-phase, normal-phase, GPC, SEC, and IEX application.

- Advanced solvent delivery capabilities. Serial flow path with pulse-free solvent delivery without the use of dampeners. Online solvent degassing and automated solvent compressibility for accurate flow. Integrated seal wash for robustness operation with all solvent types is standard.

- Up to 120 vials housed in an optional, temperature-controlled environment. Active and user programmable needle wash for low carryover. Variable injection volumes from 0.1 to 100 uL standard, and up to 2 mL optional. Supports STAT samples and auto-addition.

- Optional column heating or heating/cooling. Get the flexibility of running multiple methods on demand with optional column switching.

- Detection capabilities include photodiode array, UV/Vis, fluorescence, refractive index, evaporative light scattering, electrochemical, conductivity, and mass detection.

- An intuitive user interface, giving you instant access to system settings through the large LCD screen. Simplified daily set-upwith SystemPREP.

- Supported in Empower, MassLynx, and several 3rd partysoftware packages

- Compliance-ready.Qualification of laboratory instrumentation is an integral part of compliance with regulatory and quality standards such as GMP, GLP, ISO 17025, USP <1058>, and others. The Alliance HPLC System supports Waters Empower-based automated system qualification tool (SQT), which minimizes the time and cost associated with annual qualification.

Sepiatec - Supercritical Fluid Chromatography System

Parallel HPLC / SFC

Model: Sepmatix 8X Screening HPLC

The Sepmatix 8x Screening HPLC system is working with eight channels in parallel. The system only uses one external HPLC pump. The flow is separated by the patented Sepmatix Flow Control into eight channels, and the flow in each channel is precisely measured and regulated throughout the entire run. Together with an autosampler and an 8x parallel working detector, the result is an unbelievable compact HPLC system which will instantly enhance the throughput of every research and development laboratory eight times over.

It is not necessary to spend time adapting methods to the new system or to purchase any new costly HPLC columns. The users can continue to use all the methods and separation material that they were using with their conventional HPLC systems.

The Sepmatix 8x Screening system can separate substances on eight different separation columns simultaneously. This significantly increases sample throughput.

The system consists of three modules: an 8x Flow Control low viscosity version with flow rates of between 0.25 to 1.25 ml/min; an autosampler with syringe pump which injects samples from standard microtiter plates or deep-well microtiter plates onto eight columns (also suitable for vial racks); and an 8x Diode Array Detector with eight analytical flow cells applicable for the spectral range of 200 to 600 nanometres.

The required space for the Sepmatix system is only 55 x 55 x 90 centimetres (W x D X H).

The Sepmatix 8x Flow Control is available as an analytical version (with flow rates from 0.25 to 1.5 m / min per channel), a semiprep version (1.5 to 6.0 ml / min per channel) and a prep version (6.0 to 20 ml / min per channel).

Enquiry Now

Model: Sepmatix 8X Screening SFC

The Sepmatix 8x Screening SFC system combines Sepiatec’s proven parallel HPLC technology with the advantages of supercritical fluid chromatography.

Eight separating columns: The result is the first SFC system with eight separating columns working in parallel, high operating speed and as yet unmatched performance.

In a space of only a few minutes for example enantiomers can be separated on eight different chiral columns at the same time. The automatic variation of the eluents makes it possible to determine the optimal chiral separation in a significantly shorter time than was previously possible.

Best peak resolution: The superb Screening Wizard Software clearly displays the separations achieved in up to 80 chromatograms at the same time. The separation with the best peak resolution is immediately discernible. The software considerably reduces the amount of time the user needs for the selection process. The overview display is extremely suitable for presentations.

As far as the Sepmatix 8x SFC systems technical features are concerned, only one CO2 pump and one modifier pump are needed. Using Sepiatec’s patented Flow Control the flow is divided into eight channels and regulated exactly by electronically controlled valves.

High Standard Equipment: A back pressure regulator, an autosampler, an eight channel diode array detector and a column oven for heating and cooling purposes are part of the standard equipment.

With minor modifications the Sepmatix 8x SFC system is also suited to chromatography using organic solvents.

Enquiry Now

PREPARATIVE SFC

Model: Prep SFC 50

Preparative Scale Separation – Compact Design

The Prep SFC 50 from Sepiatec is a compact and easy-to-use chromatography system for preparative separations on small columns by means of supercritical fluid chromatography (SFC).

The system offers the comprehensive benefits of SFC technology, such as faster separations, lower costs due to reduced consumption of organic solvents, as well as being more environmentally friendly at increased safety.

.

The Prep SFC 50 is equipped with two 400 bar high-pressure pumps with 30 ml pump heads. The total flow – at a modifier portion of 40 % – amounts to 50 ml/min. This way, chromatography columns with inner diameters ranging from 4 to 16 mm, and a length of 250 mm can be used.

The column oven, containing the chromatography columns together with the injection valve and the UV flow cell, is heatable up to 70° C so that a uniform temperature is ensured. The Prep SFC 50 system is available with 8 gas-liquid-separators.

As fractions are collected in unpressurized state, not only safety is increased, but also handling is simplified, and limitations with respect to the size of fraction volumes do not exist. This option proves to be extremely convenient when working with stack injections.

As the dimensions of the Prep SFC 50 together with the integrated system controller and 15.6” touch screen amount to only 56 x 60 x 88 cm (W x D x H) this system requires a minimum of space in the laboratory. A separate computer or monitor is not necessary.

The equipment of the Prep SFC 50 system includes:

• A high pressure pump for CO2

• A high pressure pump for modifiers

• An adjustable back pressure regulator

• A syringe pump for sample injection

• A UV detector

• An integrated system controller

• A 15.6“ touch screen

• USB connectors, Ethernet and HDMI connector

• The Prep SFC control software

Enquiry Now

Model: Prep SFC 250

Preparative Scale Separation – Compact Design

Sepiatec’s new Prep SFC 250 system is a compact benchtop unit designed for preparative separation using supercritical fluid chromatography. Measuring just 72 x 60 x 88 cm (W x D x H) the system offers all advantages of SFC technology such as fast separation, reduced consumption of organic solvents, lower costs, improved environmental compatibility and increased safety.

The Prep SFC 250 system uses two high-pressure pumps fitted with 150 ml pump heads. Total flow rates of up to 250 ml of supercritical fluid per minute can be achieved at a modifier portion of 40%. This allows the operator to use separation columns with internal diameters of 15 to 30 mm and lengths of 250 mm.

Due to its compact design, the footprint of the Prep SFC 250 system is comparatively small and precious laboratory space can be saved. The clearly arranged assembly of the Prep SFC 250 system allows easy access to all of its modules. The fractionation module includes a selector valve and 9 gas-liquid separators (1 for waste). It is designed for 8 fraction bottles with a volume of 1 litre each. Due to the flexible outlets even bigger sample containers with volumes up to several litres can be used.

A system controller with current performance characteristics is built into the device. There is no need for a separate computer or monitor, and no additional bench space is required.

The very user-friendly Prep SFC control software runs the entire device and contains functions such as stack injection, peak detection and on-the-fly editing. Data is entered via the 15.6‘‘ touch screen, which is placed ergonomically on the upper front of the Prep SFC 250 system.

The equipment of the Prep SFC 250 system includes:

• A high pressure pump for CO2

• A high pressure pump for modifiers

• An adjustable back pressure regulator

• A syringe pump for sample injection

• A UV detector

• An integrated system controller

• A 15.6“ touch screen

• The Prep SFC control software

• An additional computer at a separate work site can also be connected.

Enquiry Now

Model: Prep SFC 660

The Efficient Solution for Preparative Separations

The Prep SFC 660 system, developed by Sepiatec, represents a powerful solution for preparative separations by means of supercritical fluid chromatography (SFC). The unit has been designed for flow rates of up to 660 ml/min at a modifier portion of 40 %.

All the advantages of SFC technology are combined: Quick separation, a reduced consumption of organic solvents and thus cost, increased safety and an environmentally friendly process.

In spite of its remarkable capacity, the Prep SFC 660 system features a compact design with measurements of 150 x 68 x 178 cm (W x D x H), so that integration within a walk-in laboratory hood does not create any problem. Additionally, below the unit, several large fraction vessels or a safety cabinet for solvents may be placed.

The Prep SFC 660 is equipped with three 400 bar high-pressure pumps. A CO2 pump with 400 ml pump head, a modifier pump with 250 ml pump head and a modifier/add-on pump with 150 ml pump head. The total flow – at a modifier portion of 40 % – amounts to 660 ml/min. Up to three different organic modifiers can be mixed and used for separations.

Besides the column mounting, the injection valve and the UV flow cell are also integrated within the column oven, which is heatable up to 50° Celsius. Separation columns with inner diameters between 25 and 50 mm and a length of up to 800 mm are admissible.

When working in “Single Mode”, up to 8 fractions can be collected (CO2 flow < 180 ml/min); in “Tandem Mode” 4 fractions are available (CO2 flow > 180 ml/min).

As fractions are collected in unpressurized state, not only safety is increased, but also handling is simplified, and limitations with respect to the size of fraction volumes do not exist. This option proves to be extremely convenient when working with stack injections.

The equipment of the Prep SFC 660 system includes:

• A 400 ml high pressure pump for CO2

• A 250 ml high pressure pump for organic modifiers

• A 150 ml high pressure pump for organic modifiers

• A gradient module for the mixing of modifiers

• A heatable column oven

• A backpressure regulator

• A syringe pump for sample injection

• A UV detector

• 8 gas-liquid-separators for fractions

• A powerful cooling module

• An integrated system controller with 15.6” touch-screen

• USB connectors, Ethernet and HDMI connector

• The Prep SFC control software

Enquiry Now

Model: Prep SFC M 5

Versatile SFC System for Chiral and Achiral Separations

Sepiatec’s Prep SFC M5 system is a preparative system for separating chiral and achiral samples using supercritical fluid chromatography.

The Prep SFC M5 system consists of the main module and the collector module. Both modules form a functional unit that can be configured in a variety of ways with different equipment.

The main module can be equipped with up to three high pressure pumps, a CO2 pump, a modifier pump and an optional add-on pump for separations with low modifier portions. The available options include CO2 and modifier pumps with 30 ml pump heads, 400 bar (Prep SFC M5-50) or CO2 and modifier pumps with 150 ml pump heads, 400 bar (Prep SFC M5-250).

The integrated auto sampler can accommodate two standard or two deep well microtiter plates with 24 wells and a volume of 10 ml each or racks with up to 60 sample vials with a volume of 1.5 ml each.

The heatable column oven contains up to 10 separation columns with internal diameter of 4 to 30 mm and a length of 250 mm.

Standard equipment in the main module is a UV detector for measuring in the range of 190 – 500 nm. Other detectors, such as a DAD or an ELSD, can also be connected.

An integrated system controller and a 15.6” TFT touch screen are used to input all data for sample separations. No additional computer is needed, reducing the space required for the Prep SFC M5 system to a width of just 92 cm.

The post heater and the back pressure regulator are integrated within the collector module. The continuously operating gas-liquid separator is located at the front of the collector module; it removes residual CO2 from the isolated compounds.

The Prep SFC M5 system can be fitted with a carousel fraction collector which can accommodate collection vessels with volumes ranging from 10 to 500 ml.

Alternatively, an XY-fraction collector for vials with volumes of 10 or 60 ml is available. A total of up to 195 fractions can be collected.

Enquiry Now

Core Separations

Supercritical Fluid Extraction System

Model: Supercritical Fluid Extraction System

Supercritical Fluid (SCF) extraction systems that harness true power of carbon dioxide as a solvent. Product solubility, physical make-up of raw material and most importantly, mass of CO2 per mass of raw material, pressure and temperature are critical to extraction efficiency and operating costs. These system related factors are optimized in our extraction systems to realize full benefits of CO2 processing – safe, organic and very cost-effective extracts. All the systems are manufactured under stringent quality conditions complying to ASME guidelines.

Lab and pilot-scale SCF extraction systems for processing botanicals, natural products, polymers and other fine chemicals.

Lab-scale extraction systems in 100 mL, 500 mL, 1L, 5L and 10 L extraction vessel volumes. Additional extractor volumes, flow, pressure, temperature and fractionation options are available to customize extraction systems to your needs. Reaction, RESS and SAS systems are also available for research and application with Method development.

Pilot-plant range offered with single or multiple vessels for batch and semi-continuous operations from Kilos to hundreds of Kilos of material processing. Systems in standard or custom to your application are available in 2x5L, 2x25L, 2x50L, 2x75L and 2x100L sizes.

Application :

- Extraction & Fractionation of edible fats & oils

- Purification of solid matrices

- Separation of tocopherols & other anti-oxidants

- Cleanup of herbal medicines & food products from pesticides & herbicides

- Detoxification of shellfish

- Concentration of fermentation broth, fruit juices, etc

- Flavors, spice extracts, herbs, decaffeination

- Fragrances

- Natural Food colors

- Desolvation within tablets

- Dietary supplements such as St. John’s Wort, saw palmetto, kava-kava, ginger, garlic and ginseng

- Production of denicotined tobacco

- Production of active ingredients from herbal plants for avoiding thermos or chemical degradation

- Active compounds of all kinds, including steroids and polymer / monomer separation

- Precision parts cleaning

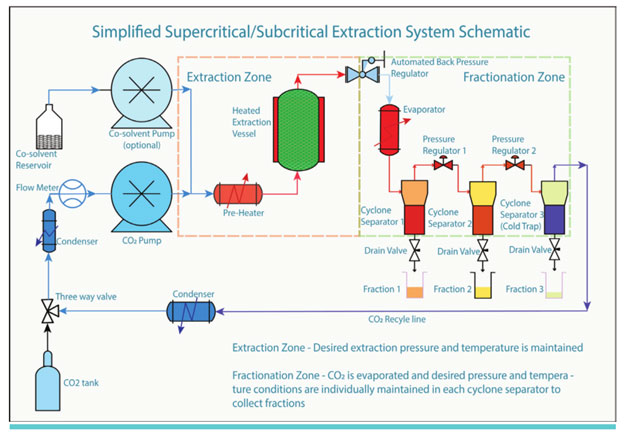

Schematic of SFE System

Particle Formation :

RESS Module

A RESS module comprising of following parts in conjunction with system. Using a non-stirred vessel will be used to allow RESS operation in the SFE system.

Specifications:

- RESS particle formation vessel: 1

- Volume: 100 mL

- Pressure: up to 5 bar

- Temperature: Ambient

- Heated Nozzle Assembly with following nozzle discs: 10, 25, 50 and 100 micron sizes

- Dissolution vessel: Extraction vessel from SFE system

- Safety device on particle formation vessel

SAS Module

A SAS module comprising of following parts in conjunction with system from SFE will be used to allow SAS operation in the SFE system. Co-solvent pump option has to be selected for SAS module option to work.

Specifications:

- Uses existing vessel from SFE system 500mL

- Pressure: up to 600 bar

- Temperature: up to 100 ˚C

- Nozzle Assembly with following nozzle discs: 10, 25, 50 and 100 micron sizes

- Safety device on particle formation vessel

| System Models and Features | ||

| Specification | Lab-Scale | Pilot-Scale |

| Flow Rate (Kg/hr) | up to 30 | up to 600 |

| Vessel Volumes(L) | 0.1 to 10 | 10 to 100 |

| Basket Volumes(L) | up to 5 | up to 100 |

| Pressure (Bar) | 400 / 689 | 689 |

| Separators | up to 3 | up to 3 |

| Temperature (deg C) | Amb – 150 | Amb -150 |

| Automated BPR | Std | Std |

| Co-solvent Pump | Opt | Opt |

| CO2 Recycling | Opt | Std |

| Flow Meter | Opt | Std |

| Computer Control & Automation | Std | Std |

| Safety Features | Std | Std |

Installation of SFE System:

Samples extracted using SFE System